In many types of applications, metal to metal parts are a constant source of excessive wear, noise, transfer of vibrations and a range of other potential problems and issues. To solve these problems, and to provide a seal, OEMs have several possible options.

The Value of Bonding Rubber to Metal

In the past, one of the most common options was the use of gaskets or rubber and synthetic types of seals. While these products are effective and they can be replaced as needed, they also have a relatively short life cycle, and they are an additional cost in the design. It is also an extra step in the fabricating and manufacturing process, with an improperly placed gasket or seal often causing significant problems for the consumer.

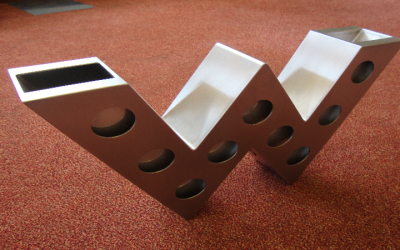

A better option is to use rubber to metal bonding processes to completely bond the rubber component directly to the metal part. Through the use of advanced types of adhesives, the bonding is very durable. It eliminates the problems with gaskets and seals slipping and moving. In fact, the rubber to metal bonding process is so complete and precise, these types of parts are used in the aerospace industry, as automotive parts, and in medical equipment and electrical components.

Specifics of the Process

The key to effective, precise, and top quality rubber to metal bonding is to use a company with extensive expertise and experience in the process. It is essential for the metal component to be correctly prepped prior to the application of the adhesive and the rubber components.

The top companies offering this process can work with a variety of different metals and alloys. It is essential to the durability of the bond to match the alloy with the adhesive and to set up the process specific to the materials. Typical metals used in rubber bonding including steel and aluminum, with brass, copper, and beryllium also used in specific types of applications.