There are specific parts and component to any electronic device or component that play critical roles. While they may appear simple at first glance, and they may even be passive in the flow of power or signal through the system, they have to be precisely designed, configured and manufactured for the system to work.

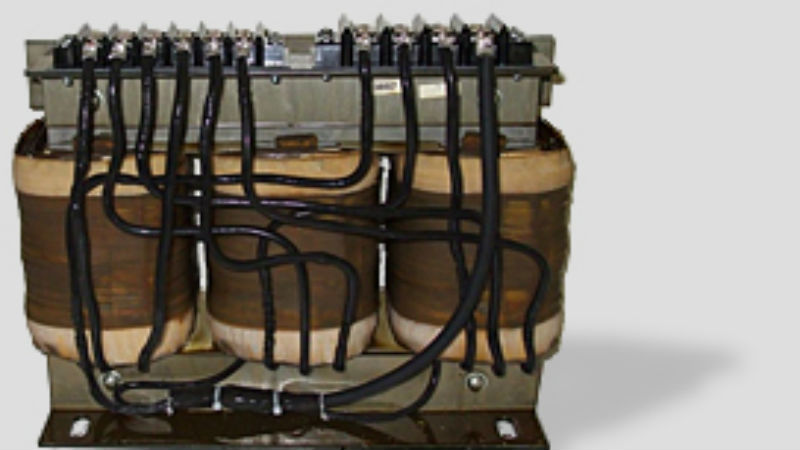

An inductor is one of those passive components. It is a relatively simple and basic component that includes a core and a winding. The core is usually made of a plastic material or a ferromagnetic maaterial, and the windings are created from a wire. The winding and the core material has to be carefully selected, as does the specific winding pattern.

There are standard options in inductors, which are readily available through any electronics supplier. However, for custom inductors, working with a specialized manufacturer is critical to ensure the correct design and configuration to maintain the correct inductance.

New Equipment Design

One of the challenges in advanced technology is to constantly move to make components smaller and more compact, even with large systems. As the overall design of electronics becomes smaller, it is necessary to create custom inductors to allow for this downsizing of components without sacrificing the ability to provide the power needed.

This can be accomplished by modifying the shape, which can be linear, bead-shaped or toroidal, as well as the winding pattern and the wire. Through the combination of the shape, the winding pattern and the core material, the energy passing through the inductor is stored and released through the system as required.

The specific winding pattern is critical for the inductance rate. Additionally, the overlap of the winding and the specific type of wire also play a very important role. Working with a company specializing in custom inductors allows these components to be precisely developed for any type of electronic component to the exact requirements for the system.