Every neighbourhood has a pharmacy, so getting treatment for your disease is only a short walk from your home. But have you ever considered how medications are acquired? A regular individual could never understand the intricacy of the technology needed to combine the many chemicals and medications for medicines. To put it simply, viscosity has an impact on how successful the high pressure homogenization of nanoparticles is. Before you can estimate the viscosity of your sample, the process is carried out by expert high pressure homogenizer manufacturers.

The different homogenizer types and their uses

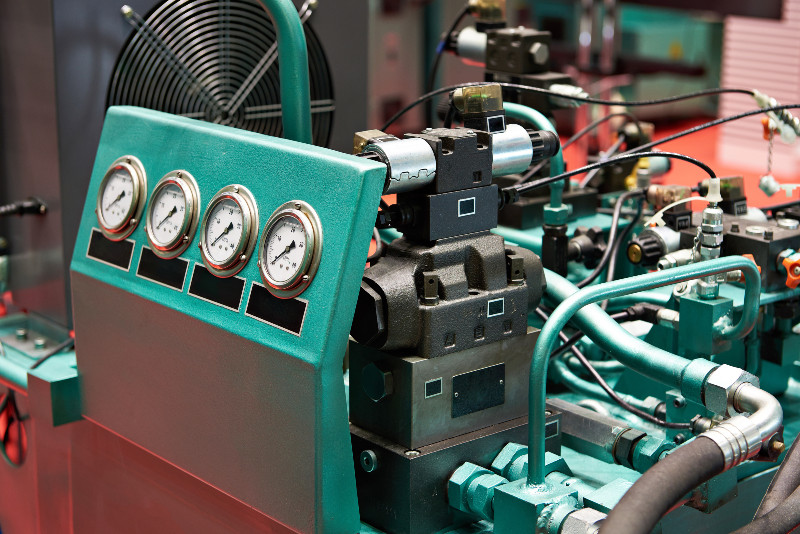

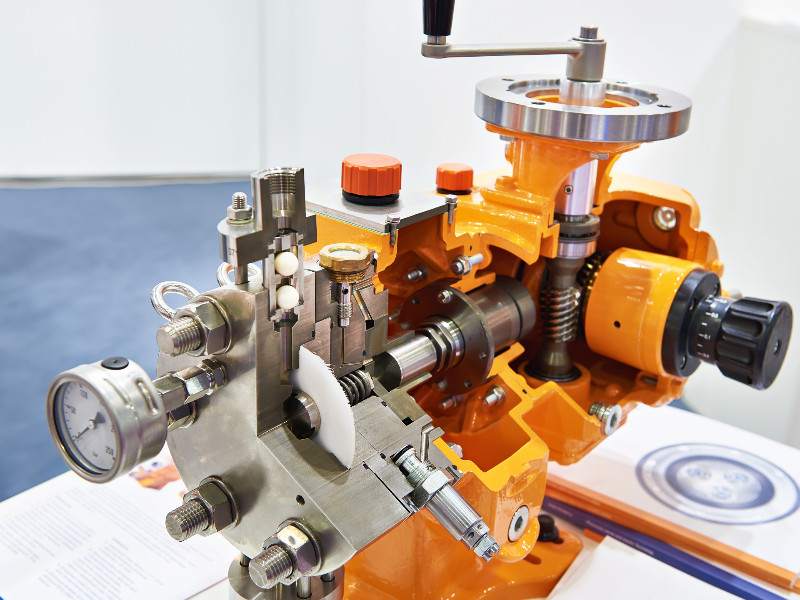

High pressure homogenizers – A high pressure homogenizer is a device that is created in a way that enables the material to be pressed through tiny holes, just as the name would imply. The sample is forced to travel through confined areas under high pressure. For this to function well, the substance must be in a liquid form that allows for efficient pumping.

Ultrasonic homogenizers – They are mostly dependent on pressure waves forming bubbles and are not much impacted by the viscosity of the substance. The energy that is produced as the bubbles burst aids in the mixing. This works up to a specified point in the material’s viscosity range and then halts operations once that point is reached. Ultrasonic homogenizers are unable to treat densely viscous materials.

They cannot homogenise a sample whose viscosity prevents it from moving through the machinery. Despite the challenges that remain in the high pressure homogenization of nanoparticles, certain techniques can help. It is suggested that the homogenizer manufacturers examine the sample’s decomposition temperature before beginning the operation. You may always combine thick components in smaller batches and keep adding surfactants and emulsifiers to make the procedure simpler.