In large industrial settings, you may see some impressive looking gate valves. In fact, gate valves (from trusted valve distributors) perform important jobs for industry today. Here is more about these special valves to give you a better idea of their purpose and benefits.

How Gate Valves Operate

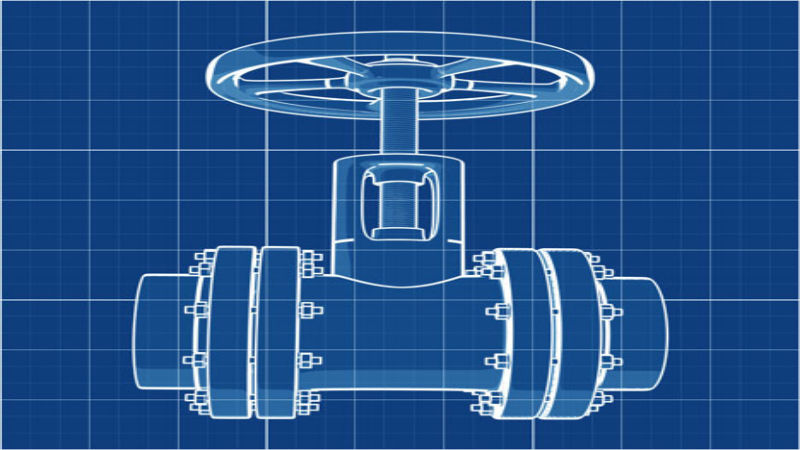

A gate valve uses a rectangular or round gate which goes up and down. When it is up, flow is allowed through the valve. When the gate comes down, it closes off the flow. Gate valves usually have round handles which turn on shafts. The shaft meshes with threads to move up or down when turned. It is easy to tell if a gate valve is open or closed just by looking at it. On the other hand, with ball valves, it is not easy to see when they are closed or open.

Benefits of Gate Valves

Because the gate mechanism can open all the way, gate valves from valve distributors allow maximum flow. This is an important feature for systems under high pressure. However, because they are commonly used in high-pressure systems, they are not recommended for flow control. For instance, partially opening the valve may damage the gate mechanism, so “on/off function is the best way to use a gate valve.

Maintaining Gate Valves

To keep your gate valves in good condition only use them for on/off applications. If a leak develops, valve distributors recommend not over-tightening the handle with a tool. You can sometimes clear sticky gate valves by opening and closing several times to clear deposits. Install new valves in an upright position. This helps to keep deposits from forming inside the valve body. To test your gate valve, fill it with water, and apply air pressure at the other side. If you see bubbles forming, then the valve has a bad seal which should be replaced.