In the realm of metal finishing, the longevity and durability of metals are paramount, especially in industries where exposure to harsh environments is inevitable. One of the most effective methods to enhance the corrosion resistance of metals is through Zinc Nickel Plating Corrosion Resistance . This technique not only provides superior protection against corrosion but also extends the life of the metals significantly. Here, we delve into how zinc nickel plating works and why it’s considered a superior choice for corrosion resistance.

Understanding Zinc Nickel Plating

Zinc nickel plating is a process that combines zinc and nickel in a plating bath, with nickel making up about 6 to 20 percent of the final deposit. The addition of nickel enhances the corrosion resistance of the plated layer significantly when compared to traditional zinc plating. Here’s a breakdown of the process and its benefits:

- Electroplating Process: : Metals are submerged in a solution containing zinc and nickel salts. Through electroplating, the zinc-nickel alloy is deposited onto the surface of the base metal.

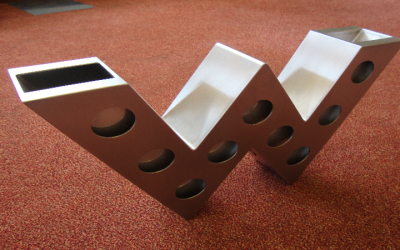

- Uniform Coating: : The process ensures a uniform coating, even on complex geometries and sharp edges, which are often vulnerable points for corrosion.

Benefits of Zinc Nickel Plating

Zinc nickel plating offers numerous advantages over other types of metal finishes:

- Enhanced Durability: : The alloy provides a tough, hard-wearing coating that resists wear and tear from physical and environmental stressors.

- Superior Corrosion Resistance: : Zinc nickel plated metals can withstand the rigors of harsh environments, making them ideal for automotive and aerospace applications where exposure to moisture and salts is common.

- High Thermal Stability: : The plating maintains its integrity at higher temperatures, which is crucial for applications involving heat.

- Aesthetic Quality: : It offers a bright, clean finish that is aesthetically pleasing, although it can also be passivated to a black or olive drab finish for specific applications.

Applications of Zinc Nickel Plating

The characteristics of zinc nickel plating make it suitable for a wide range of applications:

- Automotive Components: : Used extensively in the automotive industry for parts like brake calipers, fuel injectors, and transmission components.

- Aerospace Parts: : Critical in aerospace for components that must endure extreme environmental conditions.

- Marine Hardware: : Ideal for marine applications due to its ability to resist saltwater corrosion.

- Electronics: : Provides conductive and protective layers on components like connectors and switches.

Environmental and Safety Considerations

While zinc nickel plating offers significant benefits, it is also important to consider environmental and safety aspects:

- Waste Management: : The plating process generates waste that must be managed according to environmental regulations.

- Worker Safety: : Proper safety measures need to be in place to protect workers from exposure to chemicals used during the plating process.

Zinc nickel plating stands out as a superior method for enhancing the corrosion resistance of metals. Its ability to provide a durable, uniform, and aesthetically pleasing finish makes it a preferred choice in various industries, including automotive, aerospace, and marine. By choosing zinc nickel plating, manufacturers can ensure that their products are not only more durable and long-lasting but also better suited to withstand harsh environmental conditions. As technologies advance, the processes and applications of zinc nickel plating continue to evolve, further solidifying its role in metal protection and finishing.