When it comes to specialized types of fabrication of metal parts and components, OEMs of all sizes and with all types of order requirements turn to sheet metal fabrication services.

By outsourcing the work to specialized sheet metal fabrication services, the OEM is assured of quality, precision parts, and components produced to exacting specifications and to exact delivery dates. This is something that is very difficult to achieve in-house and still maintain cost-effective production.

When choosing the right fabrication services, there are several things that an OEM needs to consider. The first step is always to take a close look at what is required and what the fabrication service can provide. With this in mind, it is possible to narrow down the options in companies and to select the ideal match for a single order or an ongoing order for metal parts and components.

Capacity and Capability Considerations

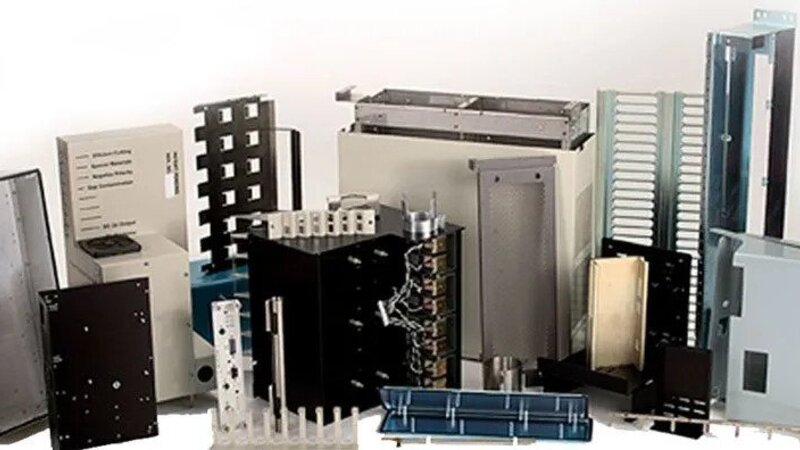

Specialized sheet metal fabrication services that provide the manufacturing of parts and components for a wide range of industries, typically have equipment and machines with the ability to work sheet metal of various thicknesses and in different metals from aluminum to stainless steel.

These same companies typically have the experience in working with particular grades and types of alloys that may be used in specific industries. Heavy equipment, rail car, and automotive parts, as well as parts for construction and HVAC systems, can all be manufactured by top sheet metal services.

Industry Reputation

Take a close look at the company’s reputation for maintaining quality control throughout fabrication before making a final choice. Delivery abilities and reputation for on-time JIT deliveries as well as stocking programs and inventory support for OEMs all highlight what you can expect in working with a sheet metal fabricator.