With Water Jet Cutting in Auburn, WA business owners can have precision parts manufactured out of materials that would otherwise be impractical to work with. Soft materials such as wood, paper, foam, rubber, and carpet can all be cut with a normal water jet cutter, while metals, stone, glass, and composites generally require the addition of an abrasive material such as garnet. Read on to find out about a few of the applications for water jet cutting below to learn more.

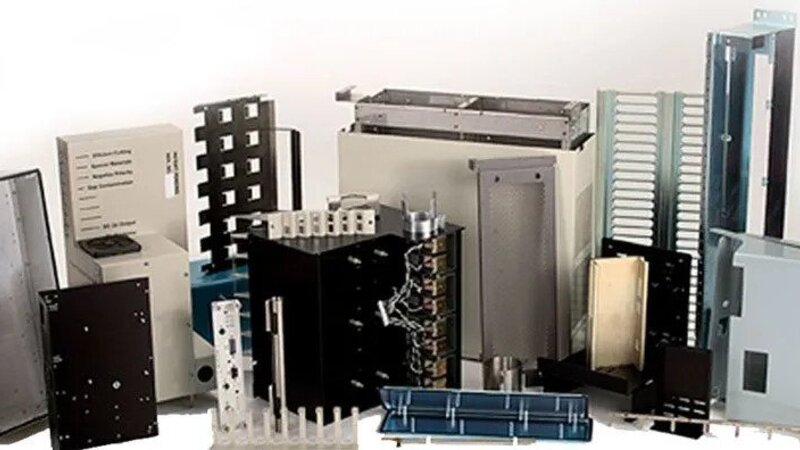

Machining Applications

There are a wide variety of materials that can be damaged by the heat produced by laser cutters. Water jet cutting allows them to be processed without any kind of heat-affected zone, effectively removing the need for secondary machining. Plus, with water jet cutting there’s far less cleanup.

Aerospace Applications

Since water jet cutting does not affect materials’ properties or temper, it can be used to process a wider variety of materials than traditional laser cutting. Aerospace engineers often use this technique for fabricating parts from synthetics, plastics, rubbers, composites, hardened steel, aluminum, and a wide variety of other materials. Since there is no heat applied, there’s no chance of parts being damaged during the fabrication process.

Architectural Uses

With Water Jet Cutting in Auburn, WA architects and contractors can have custom fixtures created out of marble, granite, tile, ornamental iron, brass, and other materials. Some materials, such as stainless steel, can even feature intricate patterns, making them perfect for decorative architectural uses.

Signs and Logos

Water jet cutting can be used to create precision signs and logos for businesses. Many commercial property owners find that the extra visual appeal of a heavy-duty sign fabricated with water jet cutting gives them an edge over their competitors. Plus, all fonts and logos can be reproduced with 100% accuracy.

Learn More Today

The applications listed above are just a brief selection of uses for water jet cutting; there are a wide variety of other uses for this technology as well. Those who wish to learn more about the process or place a custom order can visit Specialty Metals online for more information. Browse The Website today to get started.