When you run a machine shop in the Cleveland area, safety is the most important consideration. It’s important for workers to wear the right protective gear and clothing and practice safe work methods. However, machine guarding is extremely important and here are some good things to know about the practice.

What Does Guarding Mean?

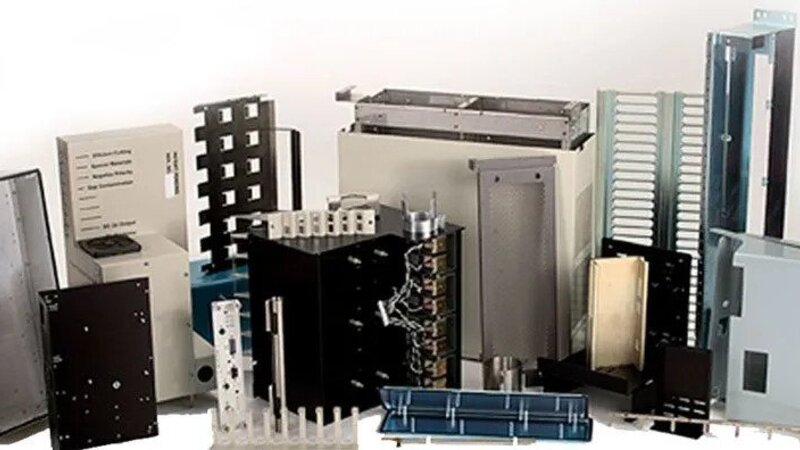

Guarding is all about the safety features of machines and equipment in the shop. It can include shields and protective structures to prevent people from reaching into dangerous areas. Guards can protect workers from flying sparks or chips and any residue that comes from machinery while it’s running. Two main types of guards are fixed perimeter and point guards.

Fixed Perimeter

Fixed perimeter is a barrier machine guarding method that protects an entire area where automated machinery is operating. For example, if you have robotic welding machinery, you don’t want anyone near the equipment while it’s running and the perimeter of the area should be fenced or guarded with protective materials. This can include safety latches (wired in series with the control circuitry) on doors leading to robotic work areas.

Point Guards

Machine shop point guards have nothing to do with basketball. They keep specific points of machinery protected from anyone reaching in and getting injured. For example, if you have a cutting shear that cuts sheet metal, you need to have a guard around the entire cutting area. This prevents people from accidentally getting caught in moving machinery. Chain drives and gear mechanisms also need point protection.

Shields

Shields are fixed devices to protect the eyes and other body parts. For example, a lathe device can throw materials at the operator while it’s running and a clear shield protects the eyes. This kind of machine guarding is used in addition to safety glasses or goggles.