Welding comes in various types and styles. Technology continues to improve and advance this form of fabrication. Of the various styles of welding, one has been adopted by the automotive industry since the 1930s. It has since become the standard for this industry. This is spot welding. Fabrication shops in Cleveland continue to use this in joining specific types of welds.

Spot or Resistance Welding

Spot welding, also known as resistance welding, is a specific style or type of welding with application to lap joints. These joints are between two metal workpieces where they overlap at the ends or edges. They come in two basic joint types:

- Full-lap

- Half-lap

The welding of the overlapping metal workpieces occurs only at small points. By applying pressure and electric current, this form of welding joins them together to produce a flush or continuous surface. Resistance welding bonds sheet metals together. It accomplishes this only for those sheets no thicker than 1/8 inch (3 millimeters).

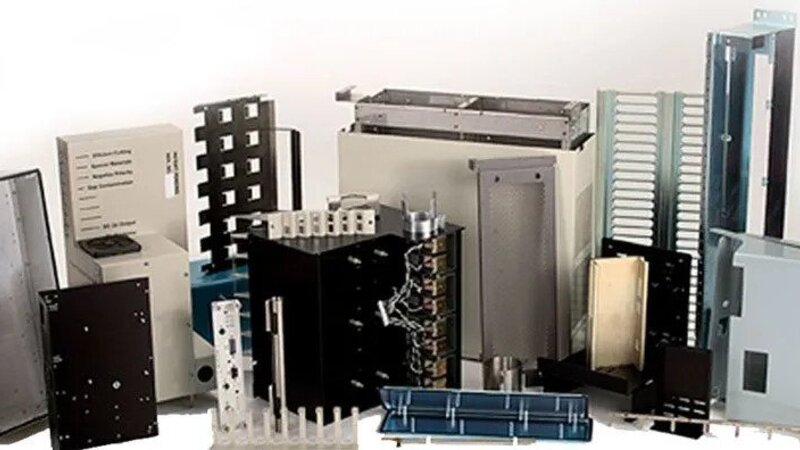

A welder in Cleveland accomplishes this using his or her basic equipment including a power supply, a weld head, and electrodes. The systems may also be automated or employ robotics to accomplish the necessary tasks.

Why Some Welders Prefer Spot Welding

Some welders prefer this type of welding. It offers certain advantages. Its application of a concentrated current flow in a short time increases the ability of resistance welding to deliver

- Precise bonds

- Controlled welds

- Reliable welds

- Does not generate excessive heat

- Can easily achieve very high welding speeds

Sport Welding

Spot welding is a common method in the automotive and furniture industries to produce strong and tight welds. Using carbon steel, stainless steel, and other compatible metals, welders can produce the type of preciseness many welders in Cleveland require to meet the specifications of their customers.